Cross-domain Innovation Technology Research and Development for Digital Yacht

Muti-function vehicle project – Engry saving yacht project

The experimental results of the energy saving long-range yacht type through ship model experiment is compared with the NPL ship type with the cruising speed of 10 knots, the resistance is reduced by 6%, and energy benefit of the resistance is reduced by 2% can be achieved when the maximum speed is 18 knots that met the trend of international hybrid power yachts, while meeting the medium and low speed long-range navigation and the need for higher speed area navigation when necessary.

The ship side anti-rolling device does not allow the appendage resistance during the yacht navigation to increase, through the hydraulic system actions of controllable foil lifting up and moving lower, and the foil action can be used to reduce the hull rolling angle effectively at low speed or at stop conditions. This Project developed the FRP hull cabinet construction method to produce the hull cabinet in the ship. Compared with the independent cabinet commonly used by the general shipyard, the fuel loading capacity can be increased by about 10% in the hull interior, and the technology transfer of this Project has been received by the domestic manufacturers for new ocean yachts.

Aluminum Super Yacht Project – Yacht Interior Prefabrication Standardization Technology

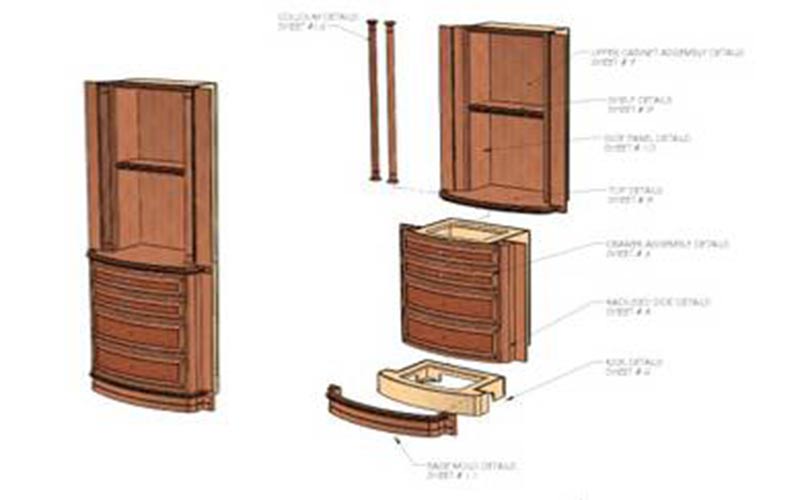

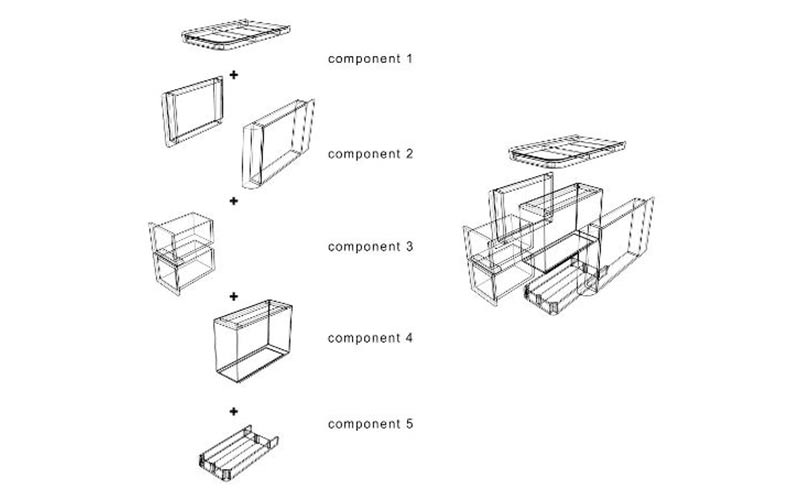

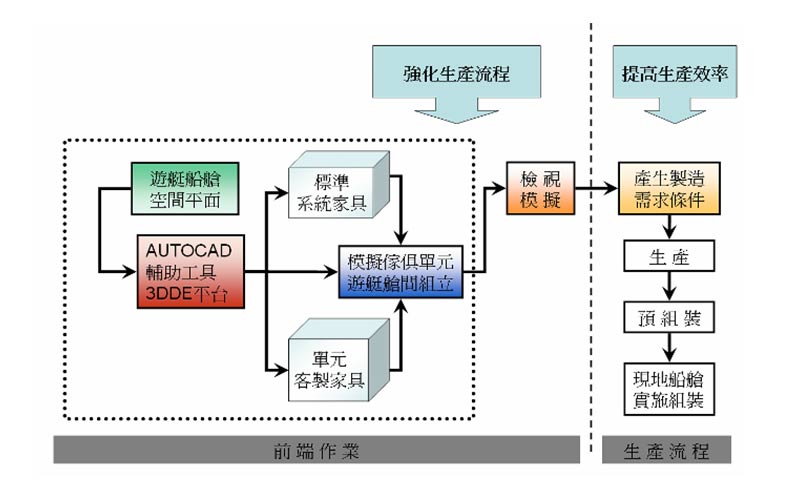

Studying the module and prefabricated concept of yacht furniture, discussing the yacht furniture modularization and prefabrication processes, and developing the technologies for the manufacture of yacht furniture modules, including the research of the furniture module manufacturing process in the yacht cabin and the development of computer-aided tools, and establish the digital modular furniture after concluded the furniture type of the yacht space, to construct the yacht furniture modularized method, and through the assistance of tools as well as the characteristics of modular furniture parameters, to assist the industry to establish the modular manufacturing technology in response to the current module manufacturing trend.

Digital Shipyard Technology and Efficient Production Integration Application Project

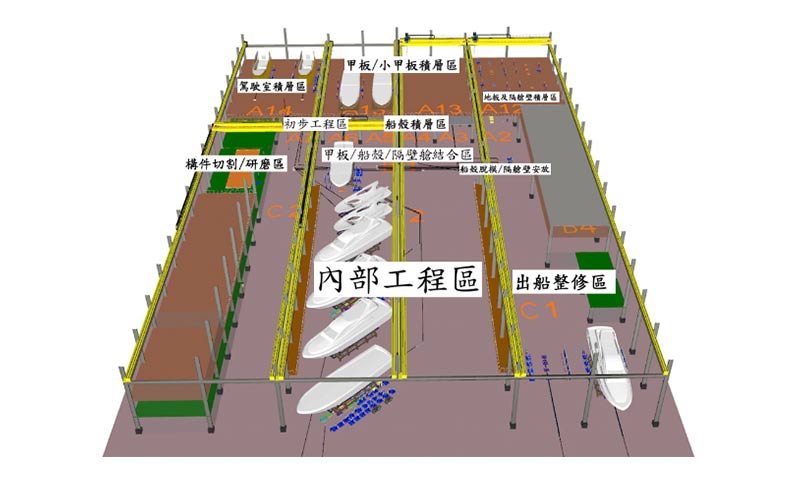

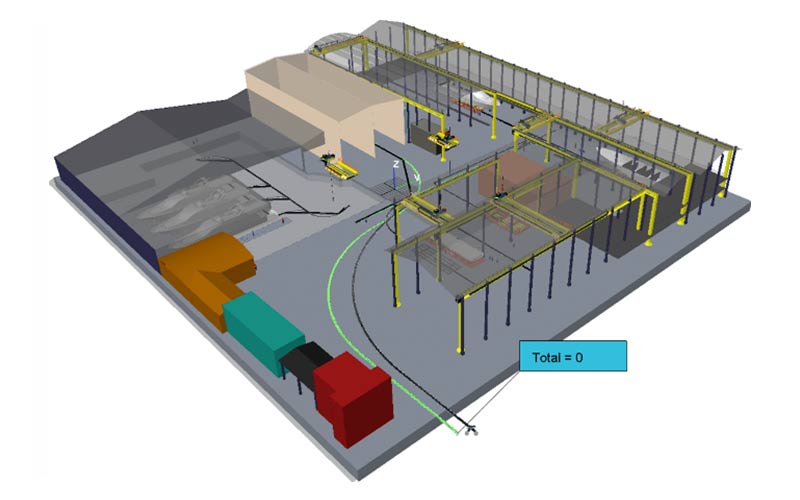

SOIC constructs the digital shipyard production layout on the existing or new yacht plant layout, input the settings of production parameters, operation process, production moving line and production resource configuration into the digital layout for dynamic simulation analysis, and establishes 3D smart components and performs the overall dynamic simulation analysis, strengthens the technical energy of domestic yacht manufacturers, improving the competitiveness of the yacht industry in international development in terms of plant planning, operation process improvement and production resource allocation. In addition, SOIC also plans to start the Work Breakdown Structure (WBS) and the output the operation process Gantt Chart are, to provide the basis of implementing future production schedule for the yacht shipyard, thereby effectively controlling production resources and estimating production capacity.

High Quality Composite Materials Molding Technology

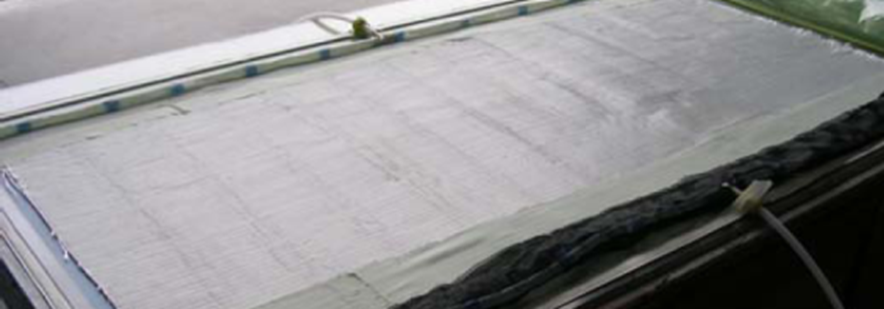

SOIC introduced the technology of “Composite Materials Resin Transfer Molding” generally known as the “VARTM – Vacuum Assisted Resin Transfer Molding” from the United States in 1999 for 12 years to date and this work method has been used in our country during this period with many excellent achievements.